Fundamentals of Optical Coatings

Optical coatings are thin-film structures deposited onto substrates (glass, plastic, or metal) to manipulate light behavior through interference. By precisely controlling layer thickness and refractive indices, these coatings can enhance reflection, transmission, or polarization—critical for applications ranging from consumer electronics to high-power lasers.

Core Principle: Light Interference

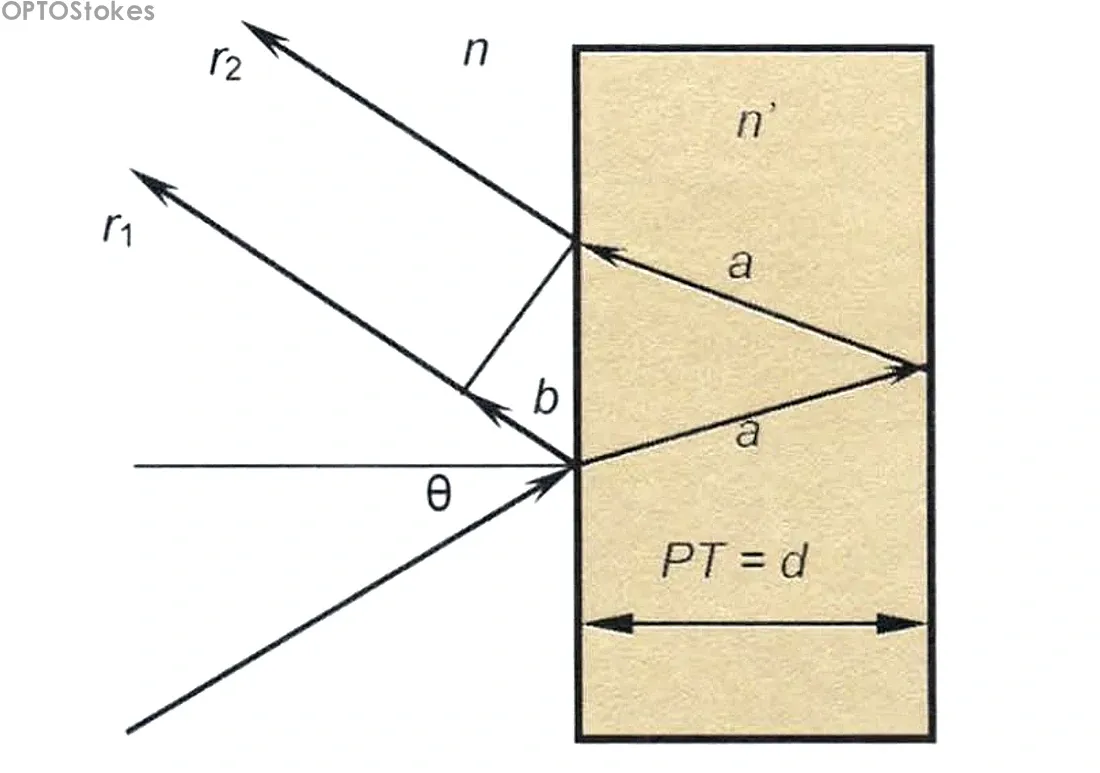

When light encounters a coated surface, part reflects off the top layer while the rest transmits. The phase difference between these two beams determines interference outcomes:

- Constructive interference (in-phase) amplifies light intensity, used in high-reflectivity mirrors.

- Destructive interference (out-of-phase) reduces reflection, achieved in anti-reflection (AR) coatings with R < 0.5%.

The formula governing this is:

\[ \Delta \phi = \frac{4\pi n d \cos\theta}{\lambda} \pm \pi \] where \(n\) = refractive index, \(d\) = layer thickness, \(\theta\) = angle of incidence, and \(\lambda\) = wavelength.

Key Deposition Techniques

Modern optical coatings rely on advanced thin-film deposition methods:

1. Vacuum Sputtering

Ionized gas bombards target materials, ejecting atoms to coat substrates. Ideal for precision AR coatings on camera lenses, achieving broadband transmission (400–700 nm) with<1% total reflection loss.

2. Electron-Beam Evaporation

High-energy electron beams melt materials (e.g., HfO₂, SiO₂) in a vacuum, forming dense, uniform films. Widely used for laser mirrors with >99.9% reflectivity at 1064 nm.

3. Sol-Gel Deposition

Liquid precursors undergo hydrolysis to form nanoparticle sols, which coat substrates via dip-coating. This method produces crack-free, high-durability films with laser-induced damage thresholds (LIDT) exceeding 14.58 J/cm² at 1064 nm.

Advanced Applications

Optical coatings address critical challenges across industries:

1. Laser Systems

Polarizing beam splitters (PBS) for 532 nm lasers require LIDT >5 J/cm² to withstand high-energy pulses. Multilayer designs with alternating HfO₂/SiO₂ layers achieve >99% polarization extinction ratio.

2. Display Technology

High-definition HUDs use dichroic coatings to reflect critical flight data while transmitting ambient light. These coatings feature

3. Medical Devices

Performance Challenges & Solutions

- **Laser Damage Resistance**: Coatings for 1064 nm lasers must balance high reflectivity (R >99.9%) with LIDT >10 J/cm². OPTOStokes’ proprietary ion-assisted deposition (IAD) reduces defect density by 80%. - **Temperature Stability**: Aerospace applications demand coatings stable up to 500°C. Alumina-based films with graded refractive indices maintain<1% reflectivity change across -40°C to 125°C.

Need Custom Optical Coatings? Partner with OPTOStokes

Whether you require:

- **Stock solutions**: Over 500 SKUs of AR coatings, polarizers, and laser mirrors ready for immediate shipment.

- **Custom designs**: Multilayer structures tailored for your wavelength (200–2500 nm), angle of incidence (0°–60°), or LIDT requirements.

Our engineers will optimize layer stacks using to meet your exact specifications—no minimum order quantity, no hidden tooling fees.

Get a Quote in 24 Hours Or leave a message with your wavelength, substrate type, and performance targets—we’ll recommend the ideal coating solution.