Laser Flat Window | Surface λ/20, Parallelism <1 arcsec

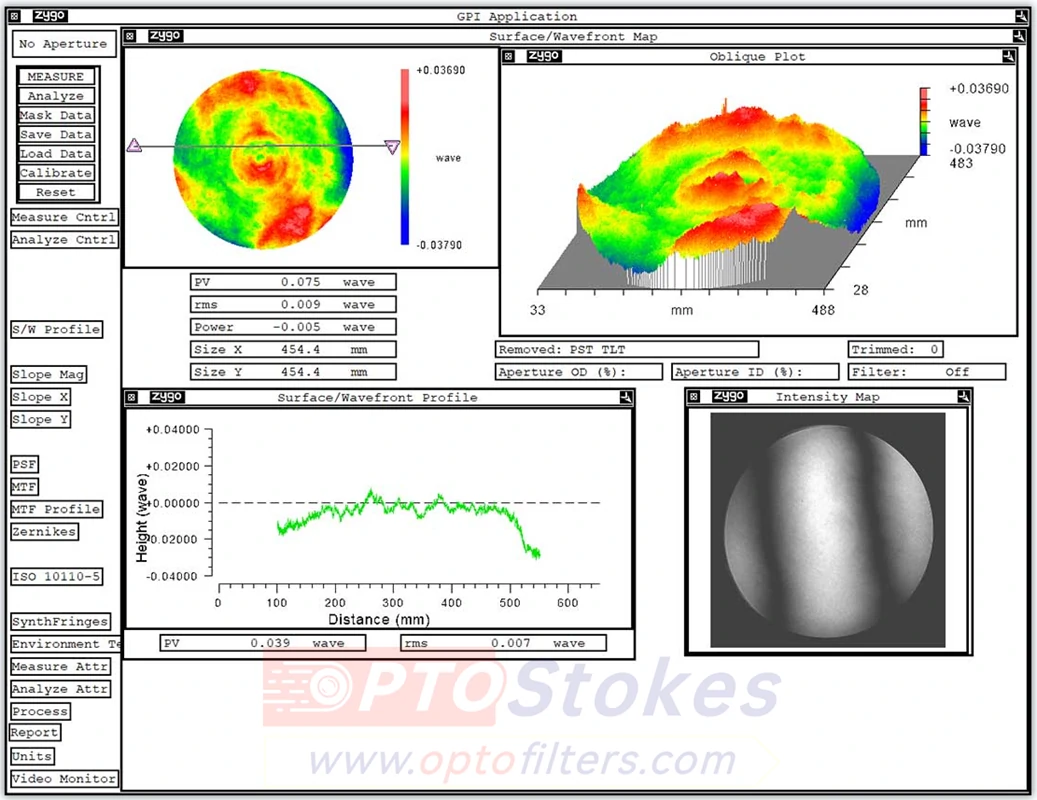

OPTOStokes Laser Flat Windows differ significantly from standard debris shields. Designed for intracavity applications, beam steering, and high-energy laser delivery systems, these optics prioritize wavefront preservation above all else. With a maximum diameter of φ620mm and surface flatness reaching λ/20, these components are engineered to minimize beam distortion and scatter in critical Laser optics systems.

Technical Specifications

Our flat windows utilize premium fused silica and K9 substrates, processed to achieve exceptional substrate quality. The strict parallelism tolerance ensures minimal beam deviation, crucial for long-path optical trains.

| Specification Parameter | Data / Value |

|---|---|

| Wavefront Distortion (PV) | Better than λ/20 @ 632.8nm |

| Surface Roughness (RMS) | Better than λ/200 (Super-polished) |

| Surface Quality (Scratch-Dig) | Better than 20/10 (High Laser Damage Threshold) |

| Parallelism (Wedge) | 1 arcsec (High Precision) |

| Clear Aperture (Outer Diameter) | φ100mm to φ620mm (Customizable) |

| Substrate Materials | UV Fused Silica (Quartz) / K9 (N-BK7 Equivalent) |

| Coating Options | High-Power AR, Metallic Mirror (Ag, Au, Al) |

Applications & Engineering Logic

The performance of a laser system is often limited by its final optical element. OPTOStokes windows serve critical roles where standard float glass fails:

- High-Energy Laser Protection: Utilizing Quartz substrates with optical coating for Anti-Reflection (AR) minimizes absorption and thermal lensing in kW-class laser cutting heads.

- Large Aperture Imaging: The λ/20 flatness over large diameters (up to 620mm) makes these ideal front windows for aerial surveillance and telescopic systems, ensuring zero image distortion.

- Interferometry Reference: Due to the high surface accuracy (RMS > λ/200), uncoated substrates serve as excellent reference flats for optical metrology.

Customization & Coatings

We offer extensive customization for OEM integration. Depending on your spectral requirement, we optimize the coating stack:

- Transmissive: V-Coat or Broadband AR for maximum throughput (99.5% T).

- Reflective: Protected Silver, Gold, or Aluminum for use as first-surface mirrors.

Optimize your beam delivery system today. Contact OPTOStokes for current inventory of custom optical components and large-format coating schedules at sales@optofilters.com.

FAQ: Laser Flat Windows

Q: Why is 20/10 surface quality important for my laser application?

A: A 20/10 scratch-dig specification reduces the number of surface defects where laser energy can concentrate. Fewer defects mean less scatter and a significantly higher Laser Induced Damage Threshold (LIDT), preventing catastrophic failure under high power.

Q: What is the benefit of 1 arcsec parallelism?

A: Parallelism measures the wedge angle of the window. A value of 1 arcsec guarantees that the laser beam passing through the window is not deviated from its intended path, maintaining alignment accuracy in precision distance measurement or targeting systems.